What we do.

High Pressure Water Solutions.

Our specialised High Pressure Waterjet Solution (HPWS) can produce flow pressures of up to 20l/m @350bar. Used for asset and facility maintenance, perfect for jetting, surface preparation, concrete scabbling, wet grit-blasting, tube cleaning, steam cleaning, oil & grease removal and much more.

Water used as a cleaning and cutting instrument is both safety-compliant and highly efficient

Ultra High Pressure Water Solutions.

For a heavy duty approach, our Ultra High Pressure Waterjet Solution (UHPWS) we offer a range of ultra-high-pressure washing solutions tailored to tackle the most demanding industrial cleaning tasks. Our equipment includes a robust trailer-mounted unit capable of delivering 18.7 l/m at 2500 bar, perfect for surface preparation, coatings removal, and general tube cleaning on mine sites and refineries. For larger or more complex operations, we utilize dynamic systems offering dual guns and up to 2800 bar pressure, ideal for cleaning tanks, vessels, and pipelines, as well as cold cutting.

Cold Cutting.

When heat and sparks aren’t an option — in explosive environments, confined spaces, or sensitive structures — cold cutting delivers. Using ultra-high-pressure water jetting, we slice through steel and concrete with zero ignition risk, no heat distortion, and precise control.

Ideal for:

Hazardous zones (e.g., oil & gas sites)

Confined space access

Structural preservation during demolition or modification

high-quality finish every time

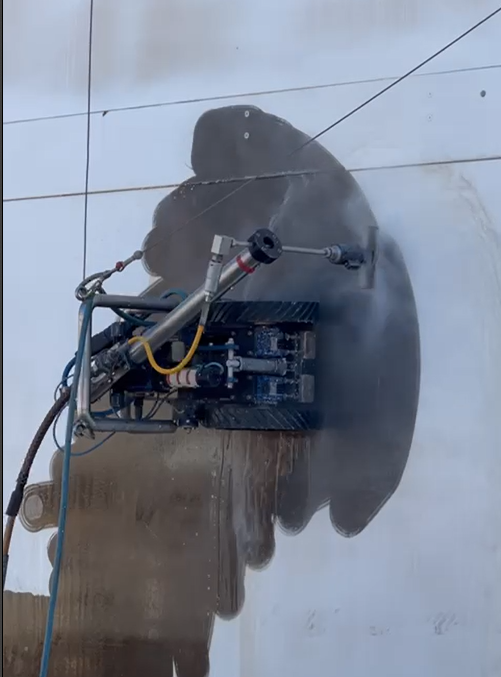

Robotics.

Our wall-climbing, tank-scrubbing robotic cleaners work like pool cleaners — only far tougher. These compact machines strip paint, rust, and scale from vertical and overhead surfaces, using ultra-high-pressure water to restore surfaces without putting people in harm’s way.

Benefits:

Up to 70% faster than manual methods

Removes workers from high-risk zones

Consistent, high-quality finish every time

Exposing Corrosion.

For aggressive descaling and larger-scale applications, we provide substantial mid-range power with automated transmission and adjustable flow rates, ensuring maximum efficiency. For specialized offshore operations, our offshore units are engineered for hazardous zones, delivering powerful results for oil and gas applications. These units are designed to enhance productivity while ensuring safety and efficiency across diverse industrial environments.

Support structure corrosion exposed. Facilitate s repairs

Exposing corrosion

Fully Trained Operators

Our crews are made up of nationally accredited Ultra High Pressure (UHP) operators, all VOC’d and site-ready.

Whether operating traditional jetting rigs or advanced robotics, safety and precision are our top priorities.

We invest in proper training so you don’t have to compromise on performance or compliance.

Coating Removal & Cleaning.

We specialise in the removal of tough industrial coatings, like polyurea, rubber, and epoxy, restoring assets to bare metal or prep-ready surfaces.

From trommel surface cleaning to general high-pressure industrial washing, we remove scale, build-up, and debris — fast, safe, and environmentally conscious.

Polyurea coating removal from trommels and drums

Surface prep for recoating, repair, or shutdown inspection

Rust, scale & paint removal using UHP jetting and abrasive methods